Owners Manual

Hitman FET with Parma Handle

(No Choke FET Model, Good thru G12 Motors)

“Selectable Throttle Curve Switches”

Fully Electronic 1:24 Controller

“All FET Design” Motor Drive “FETDrive” and Brakes “FETBrakes” “No Fuses Needed”

With Improved brake adjustability, No power blast relay required, Improved full reverse polarity protection

3rd Eye products are different, Read this manual before operation or contacting 3rd Eye with questions

Keep Precision Resistor Clean (using a DRY Q-Tip)!

Hooking Up the Hitman

o The Hitman is ONLY for use on tracks wired for POSITIVE POLARITY (brake wired to “Negative“ side of power supply/battery). Verify the polarity of the track prior to use. DO NOT attempt to connect the Hitman to a track wired for negative polarity or to Drag or HO tracks.

o ALL power leads must be connected to the correct colored terminals. Failure to do so may cause unnecessary tripping of re-settable fuses and reduce the life of the Hitman.

o When connecting the power leads, ALWAYS connect the Red power lead first! The Red lead must remain connected at all times. In the event the red lead is not hooked up, the Hitman will operate erratically (e.g. car will not operate at full power).

o Once the controller is hooked up, verify the Hitman has power – the blue LED should be on/visible.

WARNING

ABSOLUTELY NO EXCEPTIONS - Third Eye Technology has taken measures to prevent Hitman damage in the event of polarity reversal with resettable fuses. However, Third Eye Technology does not warrant the Hitman against abusive and/or repeated intentional polarity reversal. It is important to ensure the Hitman is hooked up correctly at all times.

Sensitivity Adjustment (Blue Control Knob)

o The blue knob is the Sensitivity adjustment. Turn the knob clockwise for less sensitivity (Min) and counter-clockwise as the arrow indicates for greater sensitivity (Max).

Brake Adjustment (Red Control Knob)

o The red knob is the Brake adjustment. Turn the knob clockwise for less Braking effect (Min) - the car will “roll” further before coming to a complete stop. Turn the knob counter-clockwise (arrow direction) for greater Braking effect (Max) - the car will “roll” less before coming to a complete stop.

o Note: 3rd Eye brakes go from no brakes when the knob is full Clockwise to the very onset of braking to full (best on the market). When, at the onset of brakes, with some cars the initial braking may not be too noticeable however braking action is taking place. The Hitman has improved brake adjustability that makes the brakes much easier to dial in with this product.

The 4 position Dip Switches

A cluster of 4 slide switches located on the side of the handle is the Throttle Curve Switches. Setting a switch in the up position softens the bottom portion of the throttle curve. The switches effects are additive, they all have the same weight and be set in any order, with all 4 switch up has 4 times the effect.

Reverse Polarity/Incorrect Hook-up

It is extremely importance the unit be hooked up correctly – this is a prerequisite of being a qualified racer. In the event the unit is hooked up incorrectly the unit will self –protect, by the time the connections are corrected the internal fuse will reset and operation will be normal.

If the Red Wire is not hooked up, the car will have no brakes and no full power. If the track’s brake fuse is blown, the same condition will occur.

Mush Button Installation (user installed)

Š The mush button is not standard and is a user installed option. Radio Shack P/N 275-1547.

Š Flair the buttons pins outward at 90 degrees then Install the button into the large hole in the printed circuit board so the button is facing out the back. The pins must line up with the 2 large pads directly under the hole in the buttons pins.

Š Buss wire (small wire) from the pin to the large pad below for each pin.

Š Cut the area out of the back handle so the Button is accessible

CARE AND MAINTENANCE

The Hitman is a precision electronic instrument and should be treated accordingly. To ensure optimal performance, follow the steps described below.

Do NOT:

o Throw or misuse or abuse the Hitman in any way.

o Carry the Hitman by the handle draped over the neck or place excessive strain on the entire assembly.

o Pull the power leads from the track terminals. Always disconnect the power leads one-at-a-time by “opening” the alligator clip.

o Under any circumstances oil/lubricate the precision resistor or wiper button.

o Cut away the Hitman handle. The precision resistor must remain protected from damage, dirt and debris!

o Perform maintenance on the Hitman with the power applied.

o For any reason disassemble the Power box. There are no user serviceable components inside.

*** Important *** Keep Precision Resistor Clean (using a DRY Q-tip)!

Maintaining the Hitman

*** Warning *** - Never use solvents/cleaning fluids other than Motor Spray (such as PURE contact cleaner for slot cars) to clean the Precision Resistor. Use only in extreme cases – a DRY Q-Tip will suffice for routine cleaning.

The Hitman requires minimal maintenance to achieve optimal performance:

o Handle Hardware (Required) – Do not lose the spacer at the front of the back cover or the #4 washer and nylon spacer that set over the trigger stop screw at the front of the handles circuit board. If these parts are missing “Trigger to Hang-Up” can occur due to PC board misalignment.

o Whenever the Precision Resistor shows evidence of “tracking” (discoloration across the face of the Precision Resistor where the Wiper Button travels), cleaning is recommended.

o Use a DRY Q-tip to clean the precision resistor – move the Q-tip up/down (same direction as resistor windings). NEVER use any type of liquid/chemical other than motor spray!

o Occasionally place a drop of light oil on either side of the trigger bushing.

Trigger Arm Adjustment Initial and periodic maintenance is necessary (Perform the below procedure before contacting 3rd Eye for repairs).

##Trigger Button Break-In Period##. Follow the below procedure:

When the trigger is new, the Trigger Button needs use to become fully seated to provide smooth trigger action. Sometime after use the trigger will become scratchy. When this occurs, the button will require sanding to smooth the operation. Several sandings may be required to achieve longer-term smooth operation.

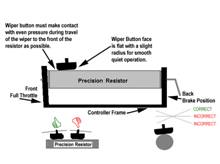

The Trigger Arm Button must remain in contact and track correctly across Precision Resistor at all times in order to function properly. Indications of an improperly adjusted trigger are inconsistent Trigger response or a scratchy/rough feeling when the Trigger is pulled during various points of throttle travel including reasonable side pressure on the Trigger (the car stutters or is inconsistent or inoperative).

If the Button and Trigger Arm are in good condition perform the following steps as necessary. This function provides smooth and quiet Trigger operation and is a critical for maximum performance.

Caution -- Use extreme care when around the throttle resistor, do not use sharp objects, damage may occur. In the event the throttle resistor is damaged, replacements are not available and repair by 3rd Eye will be necessary.

1. Remove the three (3) screws/nuts, which hold the 2 halves of the handle together. Carefully remove the Printed Circuit Board (PCB), which includes the Trigger assembly.

2. With the return spring installed, Adjust the Button tension on the Precision Resistor, by SLIGHTLY bending the Trigger Arm near the base (where it is already bent) to increase the tension or pulling LIGHTLY on the arm at the button to decrease the tension. Keep in mind that the Button must track at a slight angle with the Precision Resistor as illustrated below. If not, use your fingers to SLIGHTLY (carefully) bend the Trigger Arm until proper alignment is achieved.

3. Verify that proper tension is achieved when the Trigger slides across the Precision Resistor easily. Also, check when the trigger is slowly released and comes to rest, it must easily and repeatedly make contact with the Brake Stop. It may be necessary to repeat step 1. Note: This portion of the operation is critical.

4. Remove the Return Spring then “Pre-seat” the Trigger Button by placing slight pressure on the trigger button then cycling the button across the Precision Resistor until tracking occurs on the resistor. Blow off the tracked material.

5. Re-connect the return spring then carefully insert a 1”x3” piece of 400-600 grit sand paper between the Precision Resistor and Button length wise to the Resistor with the abrasive side facing toward the Button (AWAY from the resistor).

6. Holding the sandpaper in place and by pulling on the Trigger, cycle the Trigger Button across the full travel of the Resistor a number of times until the sand paper is loaded, then move the sand paper slightly and repeat.

7. Verify that the Trigger action is very smooth, all stops contacts and trigger travel/alignment is correct.

8. Check to see that under normal side thrust does not cause the Trigger Button to lift away from the Precision Resistor.

9. Carefully put the PCB in the Handle and re-assemble.

10. Apply power to the Hitman and verify everything is functioning properly.

Replacement Trigger Arm/Button

Contact your local track or 3rd Eye for replacement part # 003.

Any questions about products, repairs, or Track Sales locations contact Third Eye Technology

(Howard Smith) at (707) 664-1722 or E-mail at I3rdeyeguy@aol.com or thirdeyetechnology.net